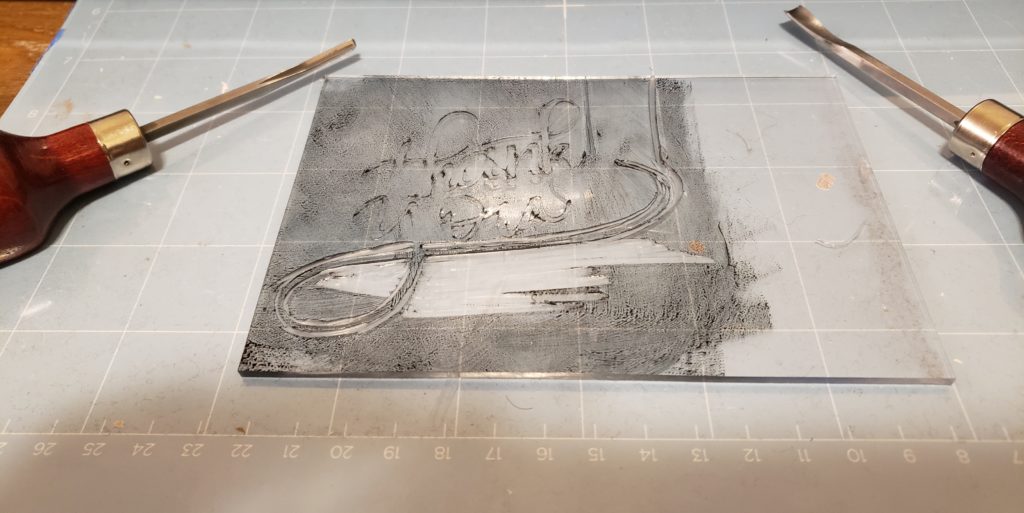

Recently, a friend asked me to do a custom order of pillows for a wedding gift. And because I can’t say no to anyone, I got out my laptop and started digitizing their invitation artwork and slapped it on some fabric and sewed a series of lovely pillowcases.

I was glad their artwork was line art as it made for an easy embroidery job. Though, they did want gold thread, which is always a pain to work with. Metallic threads constantly snap when you sew with them.

Once the job was finished and the pillows were delivered, I had some extra supplies left over and I hit up my home-girl, Jess, and asked if she wanted to learn how to sew pillowcases.

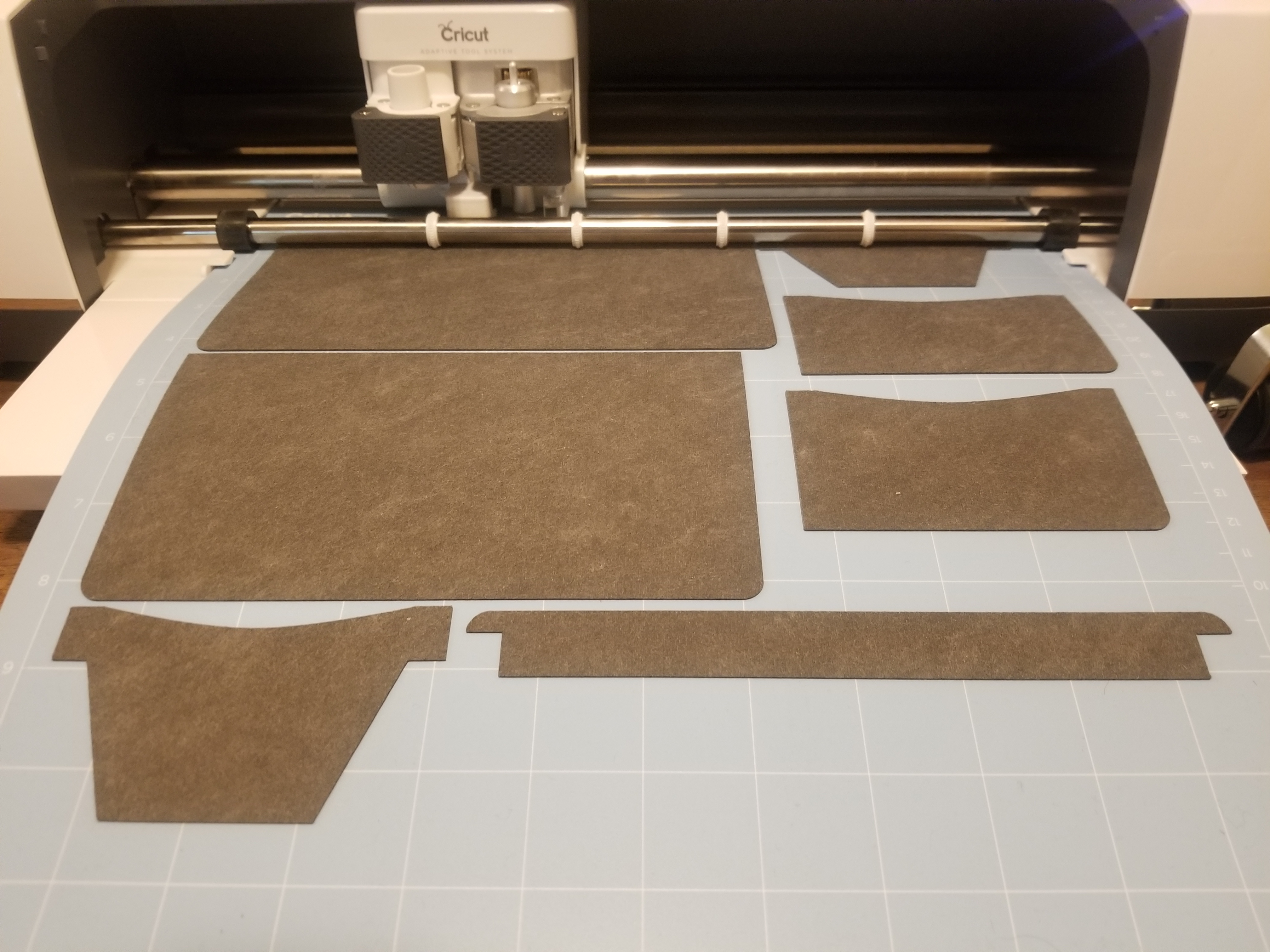

The hardest part was the cutting the fabric up for a very large pillow. We worked through folding fabric to cut on a small mat and then sewed the pieces together.

I pretty quickly realized how spoiled I am with my monster sewing machine at home that threads itself and auto adjusts for different fabrics. The fleece she picked out for her pillows was slipping and sliding all over, but with a few pointers she was sewing pillowcases like a pro!

After our little sewing session she went on to make more pillowcases and even did some fabric painting on them! She painted them so well I thought she had bought precut iron-ons.

I actually taught someone something, so that was pretty cool.