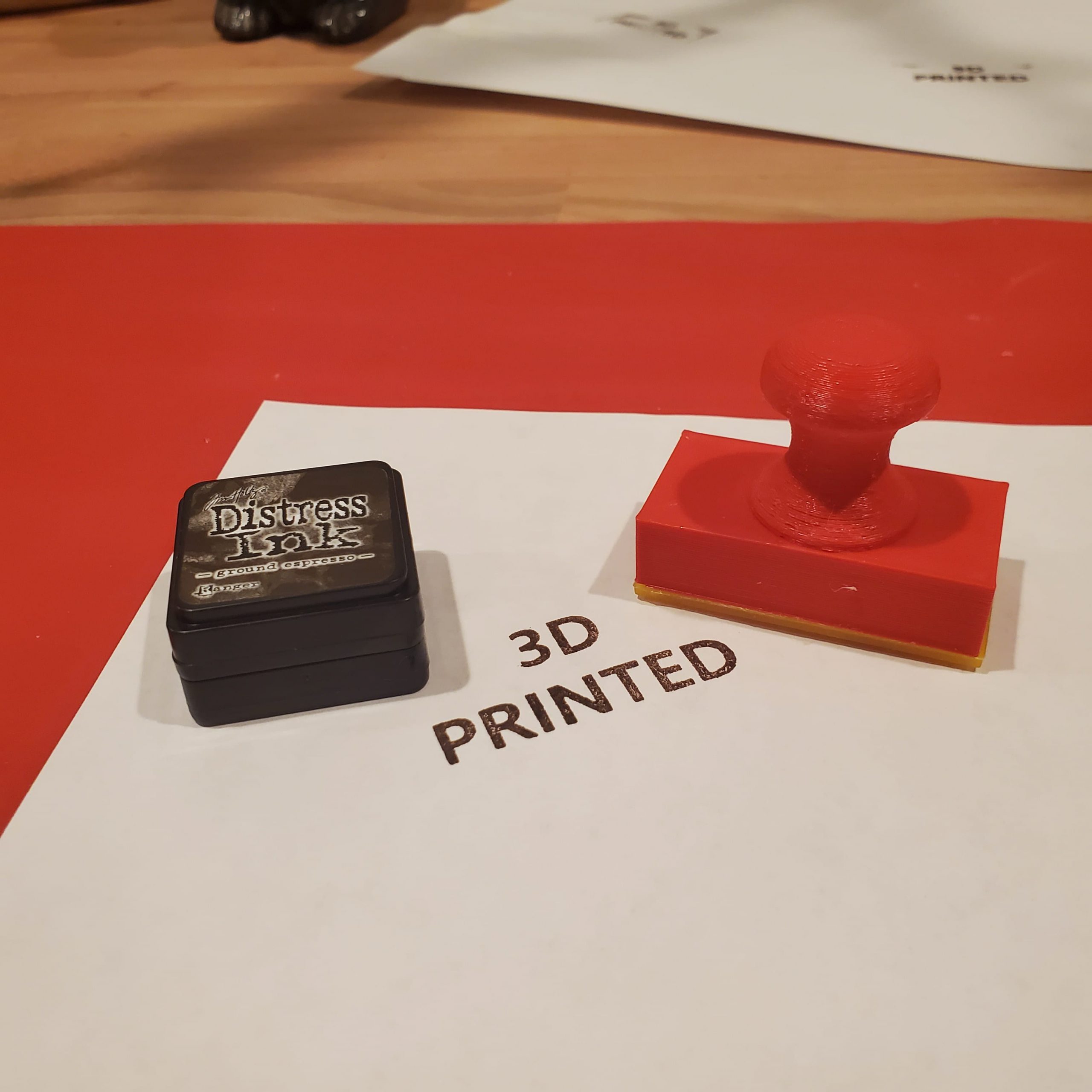

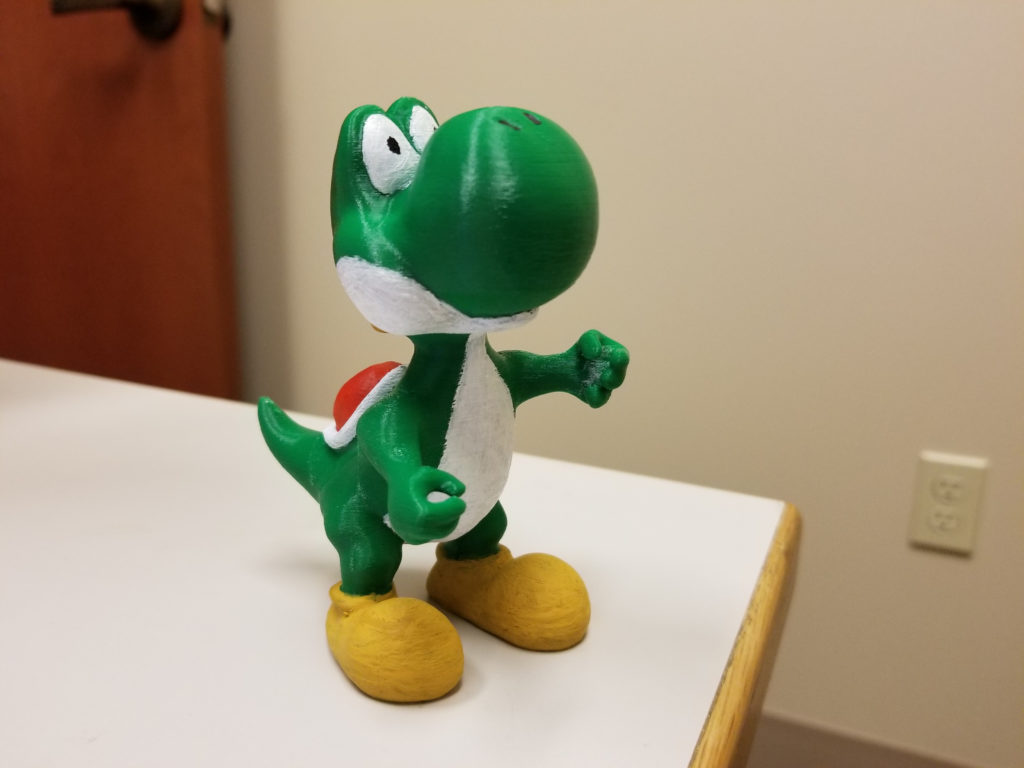

This weekend, I promised my co-worker I would spend some time doing some painting on some of the 3D items he requested. Why? Because I volunteer myself for everything.

I’ve done many many paintings, but 3D Prints are a bit hard to paint. First, they have a texture from the plastic layers (unless you do some post-processing). Second, they’re 3D, and unlike a painting, they don’t have any definite lines where the paint should stop. Third, I didn’t prime the object, because I printed it in the character’s main color so it took many layers to cover the green plastic. And last, I didn’t give it a clear coat to lock it all in, so I’m just waiting for him to accidentally scrape some of the paint off.

Basically, it can easily come out looking very messy. My co-worker seemed to really like it this morning when I brought it in, so maybe I’m being too picky. I hope it gets easier once I get a few more painted.