A while back, I had ordered another Kickstarter. Even though I’ve been burned before, it was pretty hard to resist ordering this Eazao Clay 3D Printer at a fraction of the price of anything else on the market. Kickstarters often take a very long time to materialize into a product (if they even do). Once this printer shipped it then sat in the California port for many, many months.

Eventually, my Eazao printer did show up on my doorstep and I got to work putting it together. The main unit of the printer (basically anything metal) comes preassembled, but several parts will need to be put together. If you’ve ever tried to follow an instruction manual from China, you can probably guess how frustrating it was to try and follow along. But, I did eventually get it figured out.

What I quickly learned is that the initial prep to print is a labor-intensive and very messy task. Basically, you need to fill the large cylinder with soft clay. Except, clay doesn’t come soft enough to print with, so you need to spray it with water and knead it until it gets to a peanut butter consistency.

Spray and knead. Spray and knead, Think it’s done? Nope. Spray and knead.

About 45 minutes later I finally got it to where it needed to be. If your arms haven’t fallen off yet, then you get to wedge the clay and get the air bubbles out and try to get all this paste into the cylinder without creating more air bubbles. Spoiler alert: you will create more bubbles. Lots of them.

I do realize it sounds like I’m complaining. That is because I am.

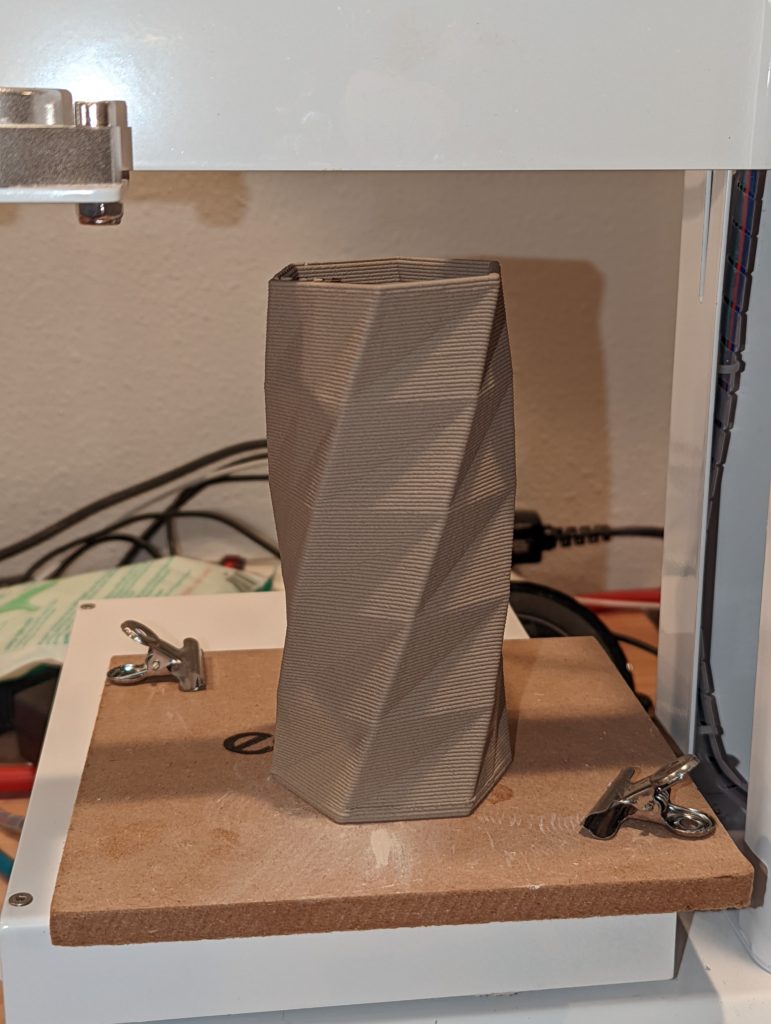

To the printer’s credit, it printed several test items flawlessly. I was shocked that it ran perfectly on my first try. The only issues arose when a bubble started coming down the tube. Trapped air will eventually blast out the nozzle and destroy previously printed rows. If you see a bubble, you might as well just scrap whatever you’re printing and start over. This also meant I couldn’t just leave it printing and wander off to do something else.

My other issue came with trying to design my own piece. The software (or slicing configuration) doesn’t allow for multiple walls, meaning everything you print will be very thin. Too thin, in my opinion. I tried printing a mug and I could only imagine one small ding and the whole thing would shatter. The software they provide is obviously aimed at very decorative pieces that show off what 3d printing can do that most ceramic artists would never be able to accomplish without a machine like this.

Finally, clean-up was awful. You had to fully disassemble everything the clay touches. Which I should have realized earlier but I didn’t know how involved it was until I got started. Having torn the whole thing apart I ended up leaving all the parts in a mixing bowl full of water for days because I lacked any tools needed to clean it. I ended up finding a very thin dowel to get the clay out of the tube that leads to the printer and long bottle brushes to try and get inside of everything. Unless you have a specially equipped sink for clay, you’re also going to be cleaning everything inside of buckets of water and then hauling them out to the yard to dump them. Clay never goes in the sink.

In the end, this was an awful full-day experience. I ended up with several cute little objects, but it wasn’t really worth all the effort to produce them. If I’m being really honest with you, I probably will never turn this thing on again.

https://tizianoberti.com/portfolio/60ml-syringe-extruder/

I’ve done a lot of whining in the post, but this is not a critique of Eazao or their machines. If you look at other printers on the market, most have this general type of setup. This is just the reality of printing clay.

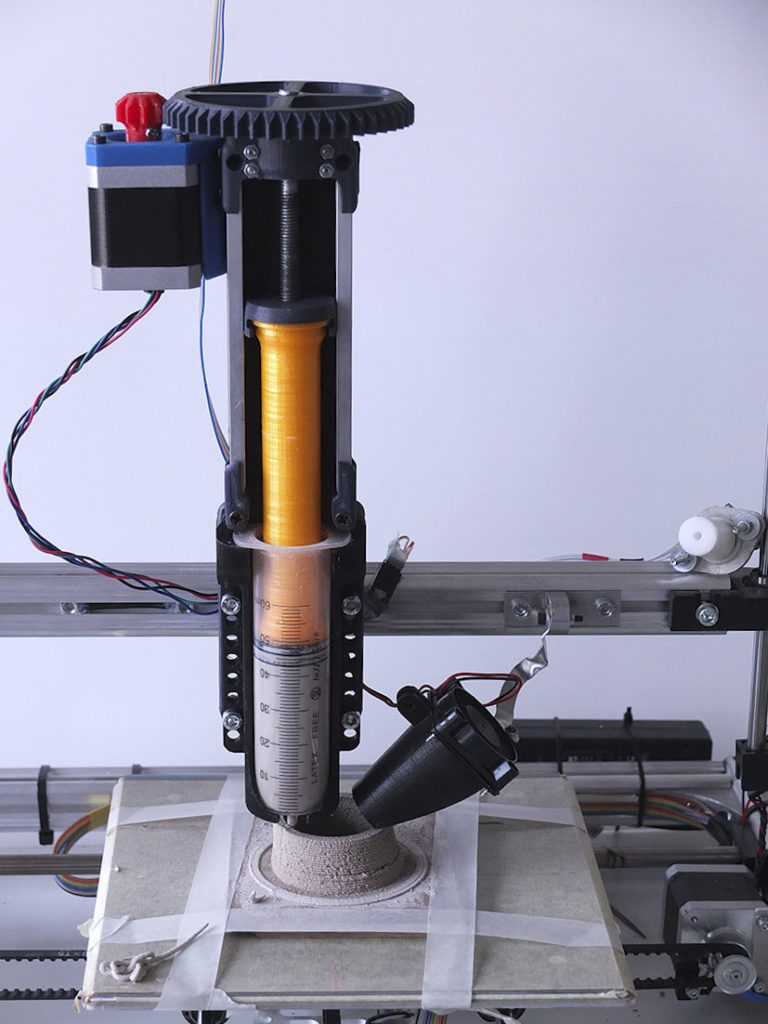

But, having this experience taught me exactly what I would look for in a clay printer. If I was ever tempted to try 3d printing clay again, it would be with a printer that uses a large syringe extruder. I googled around and found a printer like this. If you look at Tiziano’s printer above, it essentially just holds a syringe filled with clay and the machine squeezes it for you. No tubes, no augers, no cylinders, only a syringe to clean. You’d still have to prepare the clay, but this system removes half the work involved and would make cleaning up really easy.