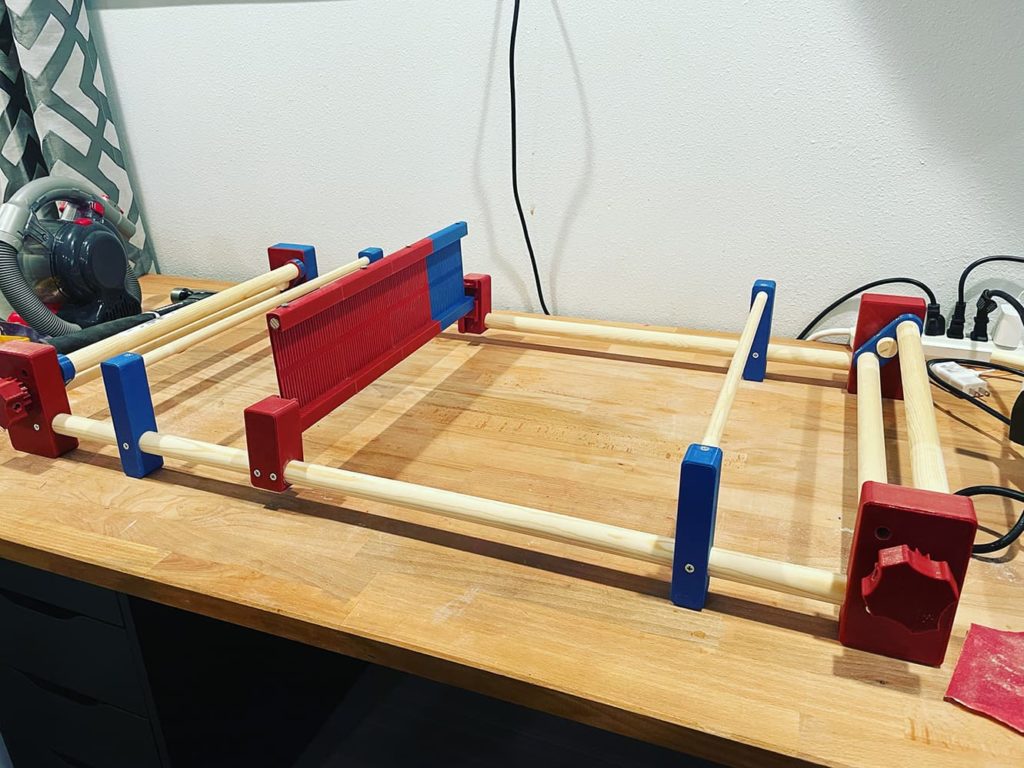

Just a quick update on the first project on the 3D-printed loom. The loom is built, now it’s time to make something!

I had been hoarding some yarn for the project and I was excited to finally get to use them. I picked out some colorful hanks to work with that I thought would look good all on their own without having to mix colors or deal with stripes. The first project was going to be using sock yarn since that I what most of my yarn is because I also knit my own socks. So even if I don’t end up weaving the yarn, they would eventually going to be used for socks.

I don’t have much time at night to put into projects so each step of the project took a night or two to accomplish.

Getting the yarn on the loom is my least favorite part, so it took two nights to get it done. Getting started took quite a while.

But once that the loom was set up the project got moving. Each night, I popped a show on the tv and just kept weaving. I need to go back and sand the heddle a bit, but overall it went flawlessly.

I had mentioned in my previous post that I was concerned about the locking mechanism on the loom, but even that worked without issue. Once there was some tension the locks I could tell they weren’t going to go anywhere.

Because I used sock yarn, it took a lot longer to get the scarf completed. Once I realized how slowly it was going I started printed the heddle for a larger yarn.

By the time I finished the scarf the new heddle was printed, put together and ready to go for the next project. The yarn I picked out has already been delivered as well.

There’s still one more heddle I can print, which is even larger for bulky yarns. I may have to try that one as well.

I’m already setting up the loom for the next project, so you may have to suffer through a few more updates on it.

Hello, do you possibly have a video of you warping this look. I have the same one, but can’t even figure out how to start, due to the fact there isn’t that lose pole attached via rope.

You’ll just tie the yarn to one of the dowels. I found a video for you that demos this loom.

https://youtu.be/J7vS2LYTtFU?si=uX3W__ZljY-RyJEE