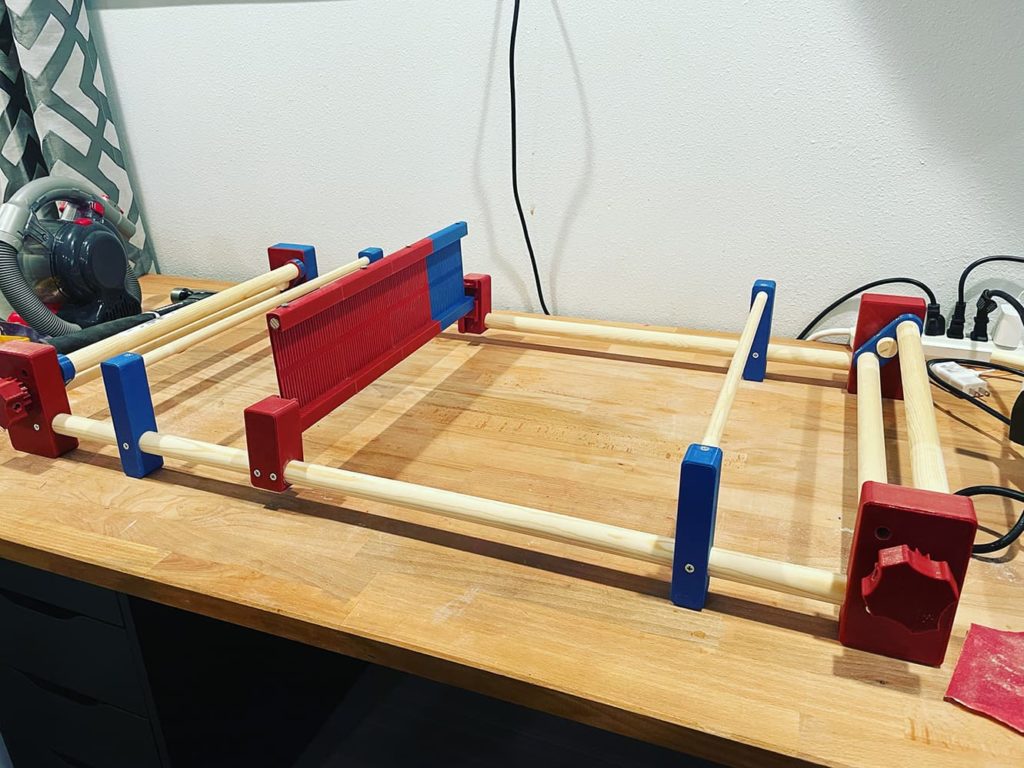

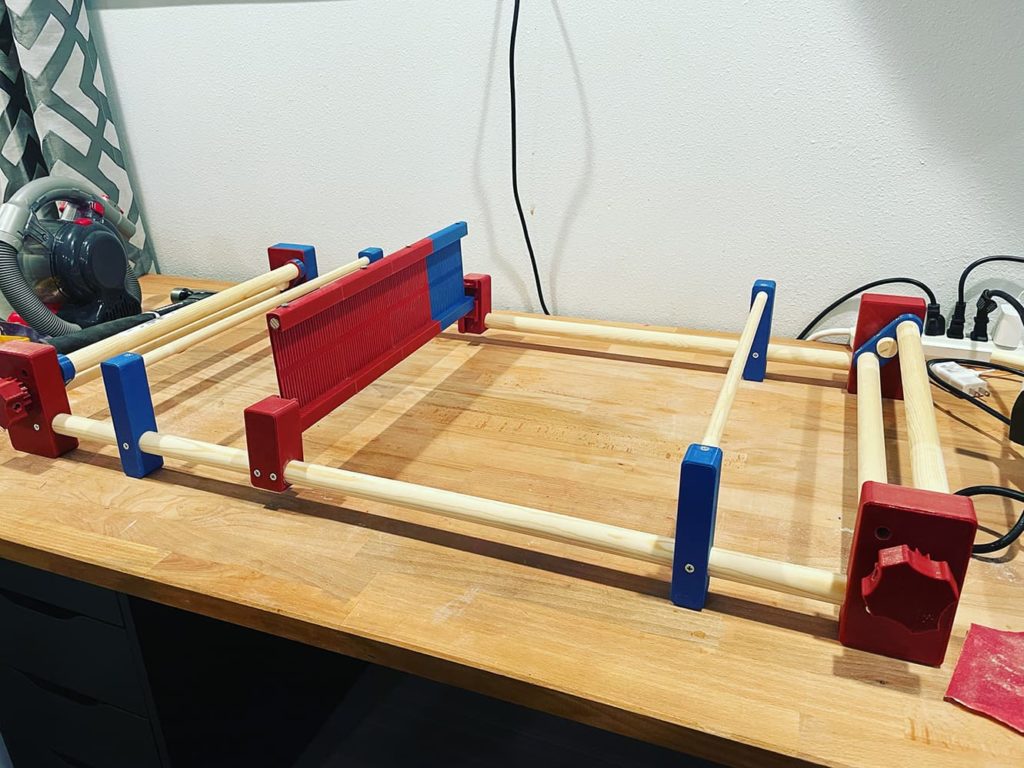

Just a quick update on the first project on the 3D-printed loom. The loom is built, now it’s time to make something!

I make stuff.

Just a quick update on the first project on the 3D-printed loom. The loom is built, now it’s time to make something!

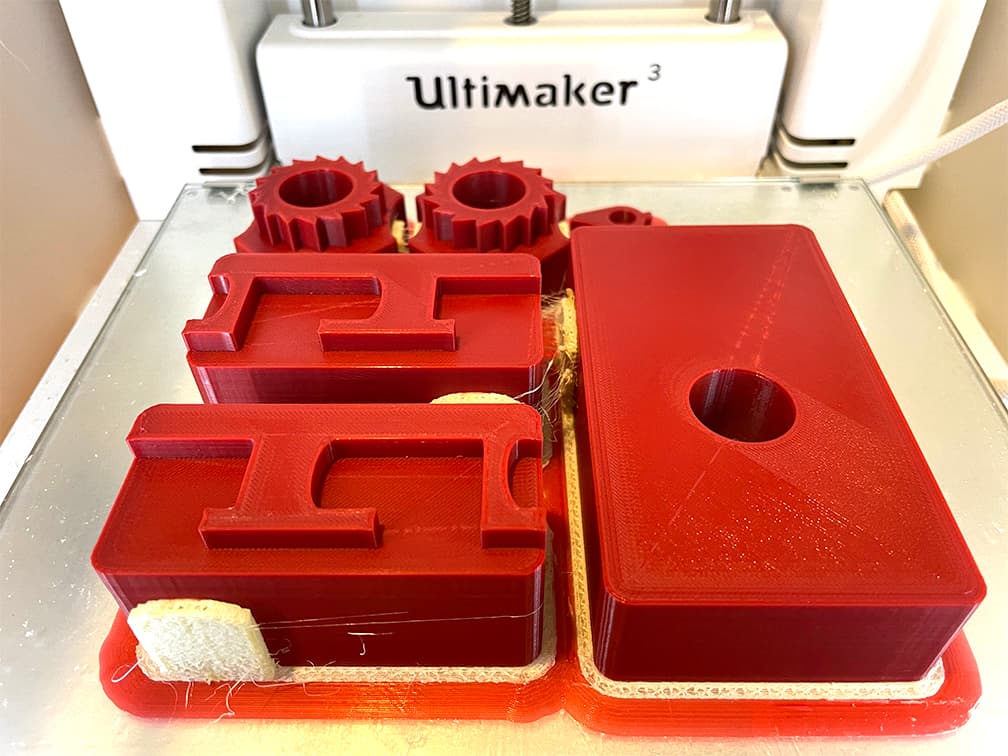

A while back, I found 3D printing files for a rigid heddle loom. A new loom had been on my wish list for years but I never pulled the trigger. Honestly, I think I’ve become frugal in my old age. Years ago I wouldn’t have thought twice about adding a new loom to my cart and checking out, but these days I just can’t justify in my mind paying hundreds of dollars for a couple pieces of wood and some plastic. Especially when I’ve had 3d printers in my home for 10 or 15 years now and I pretty much DIY everything I can.

I’ve wanted to play with a loom and try different types of weaving as long as I can remember. I shop online for them all the time but I just never pulled the trigger on actually buying one. The problem is that I look at what companies are selling and I just can’t seem to justify the price in my mind. If you look at most small looms (tabletop or lap) it really takes the most basic of woodworking skills to make one. I don’t understand how they charge hundreds to many thousands of dollars for a few pieces of wood and screws. As a beginner, I don’t really want to make one, I want to know how a professional one works first.

So the last time I was at the fabric store I saw a mini weaving loom loom on the shelf. Basically a picture frame with sawed out grooves for yarn. For a few dollars I figured I could play with this and see how interested I really am in it and maybe use up some of that scrap yarn from all the socks I’ve made.

While this is great for tapestry work, not so much for weaving. I didn’t realize you’d end up sewing your way through it since there is no heddle or shuttle and then using a rake/fork to push all your work down since there is no beater. After playing for a bit and I decided I hated it. I may make some hangings at some point with it, but my main goal is to use my piles of scrap yarn to make some scrappy scarfs.

I took to scouring craigslist for local looms. Most looms you find are large floor models, which I definitely don’t have space for nor do I want to move one. Eventually I saw an ad for a 1927 model from an artist’s estate listing. I emailed and that weekend ran over and got it.

I dragged it to the back deck and ignored the fact that I had not completed the mowing. See that gas can in the picture? Yeah, that’s supposed to remind me to do yard work and not waste my day on my arts and crafts. Adulting is horrible like that.

There was no way this thing was going in the house until it was sparkling clean. I have a severe allergy to dust and cleaning this was going to be a struggle. It had been sitting in storage since the mid-70’s. I could tell because there was brittle newspaper jammed between the layers of warp thread on the back roller.

Hours later, all the dust and grime was gone and it resembled a wood loom again.

Now I need to figure out where to put this thing since I haven’t found my second hoarder house yet. More to come once I find a place to set it up.