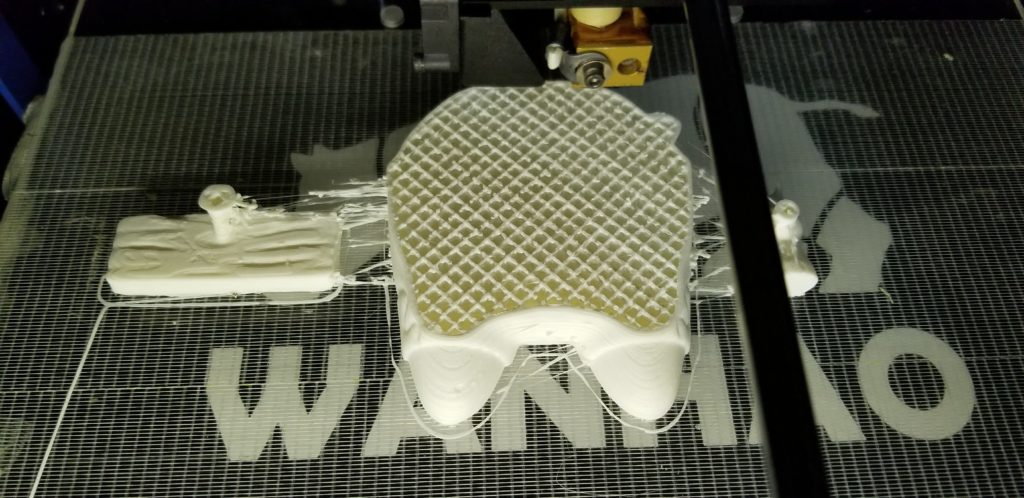

I put my Patrick Star through the Polysher machine a few times. He was in there well over an hour. I realized about then he wasn’t going to get any better than this because the machine needed to be adjusted for better printing. You can still see lines and gaps which also probably meant my PolySmooth print materials had become moist from being in the air.

Who knew plastic absorbed moisture?

So I got out my dehydrator and shoved all my rolls in there. In the meantime, I started working on calibrating my machine.

I tried using the plastic again a few hours later and it still wasn’t printing well, so I left them in the dehydrator overnight.

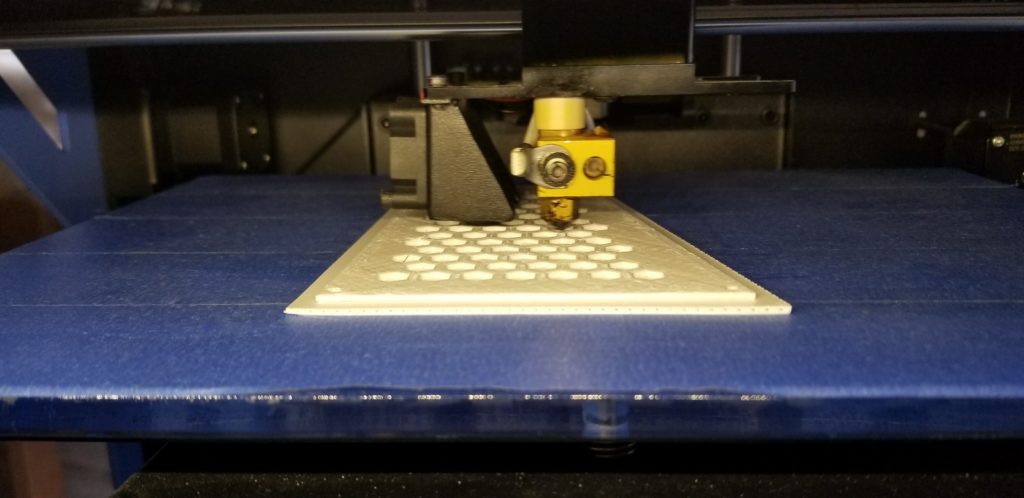

The next day, things started looking up!

A few hours later, I noticed the same gaps and problems started showing up again. The downstairs room must be a lot moister than I realized.

So, I think it’s time to start making a dry box that holds the plastic spools so they don’t keep rehydrating.

UGH! Like I needed another project.